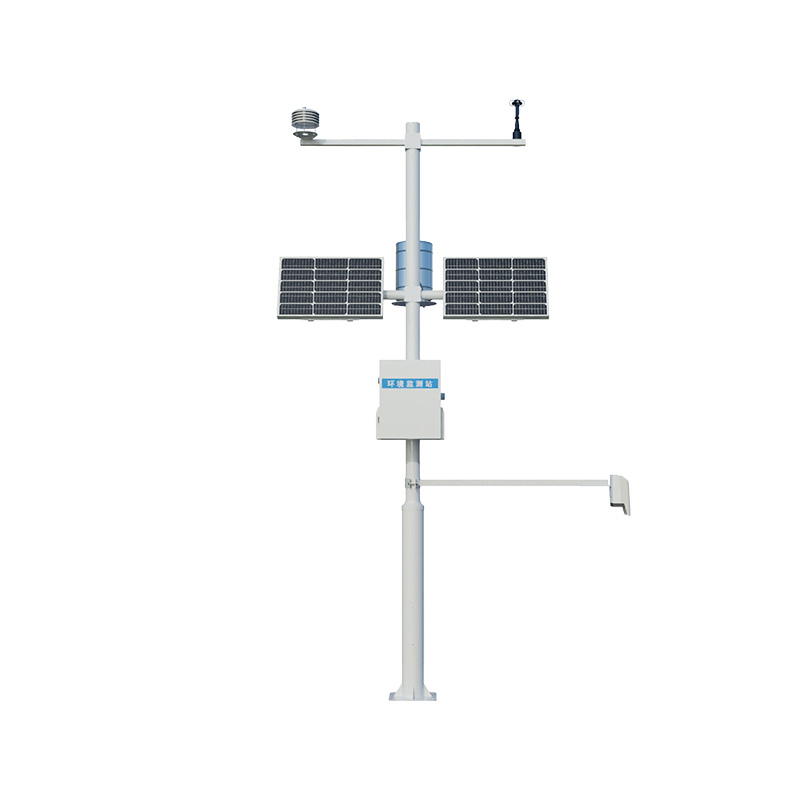

In the efficient operation chain of the photovoltaic industry, the appearance of the WX-EL3 Photoltaic Panel Hidden Crack Rapid Detection Instrument has broken the limitations of traditional detection that is difficult to capture subtle hidden dangers, making the hidden cracks inside the photovolta panels have nowhere to hide. It can quickly identify those subtle injuries that cannot be detected by the naked eye without destroying the component structure, providing timely support for the healthy operation and maintenance photovoltaic panels, avoiding the efficiency decline and safety risks caused by the expansion of hidden dangers from the source, and becoming a practical weapon in the field of photovtaic operation and maintenance.

Non-destructive testing is the core attribute of the WX-EL3 Photovoltaic Panel Hidden Crack Rapid Detection Instrument which completely changes the disadvantages of traditional detection that may damage components. Some of the previous detection methods require contact or disassembly of components, which can easily cause secondary damage to the photoltaic panels and affect subsequent use. However, this detection instrument can complete the detection without destroying the component structure and without affecting the normal operation, which not only ensures the of the photovoltaic panels but also accurately captures the internal hidden cracks, making the detection work safer and more reliable, and adapting to the detection needs of photovolic panels in various scenarios.

The rapid response capability greatly improves the efficiency of photovoltaic operation and maintenance, reversing the traditional situation of time-consuming andious inspection. In the early stage of photovoltaic panel hidden cracks, there is no obvious appearance feature, and manual inspection is not only inefficient but also prone to misgment. However, the photovoltaic panel hidden crack rapid detection instrument can complete the detection of a single component in a short time, and even in the face of a-scale photovoltaic power station batch screening, it can also be efficiently promoted, so that the operation and maintenance personnel can quickly grasp the health status of the component and the risk of hidden danger aggravation due to delayed inspection.

The strong adaptability can cover the testing needs of multiple links in the photovoltaic industry. the component production quality inspection link, it can screen out potential hidden cracks in advance to ensure the quality of the factory; after transportation and installation, it can quickly screen whether there damages caused by bumps and operation; in daily operation and maintenance, it can regularly patrol and inspect to capture new hidden cracks and build a complete health management system. The testing needs of links can be met through it, and the quality defense line of the whole chain is solidified.

Article address:

http://www.qxhjjc.com/en/newcen/1833.html

Home

Home phone

phone Product Overview

Product Overview Contact Us

Contact Us